Caldera de vapor alimentada con combustible de gas de condensación integrada de alta eficiencia del 96%

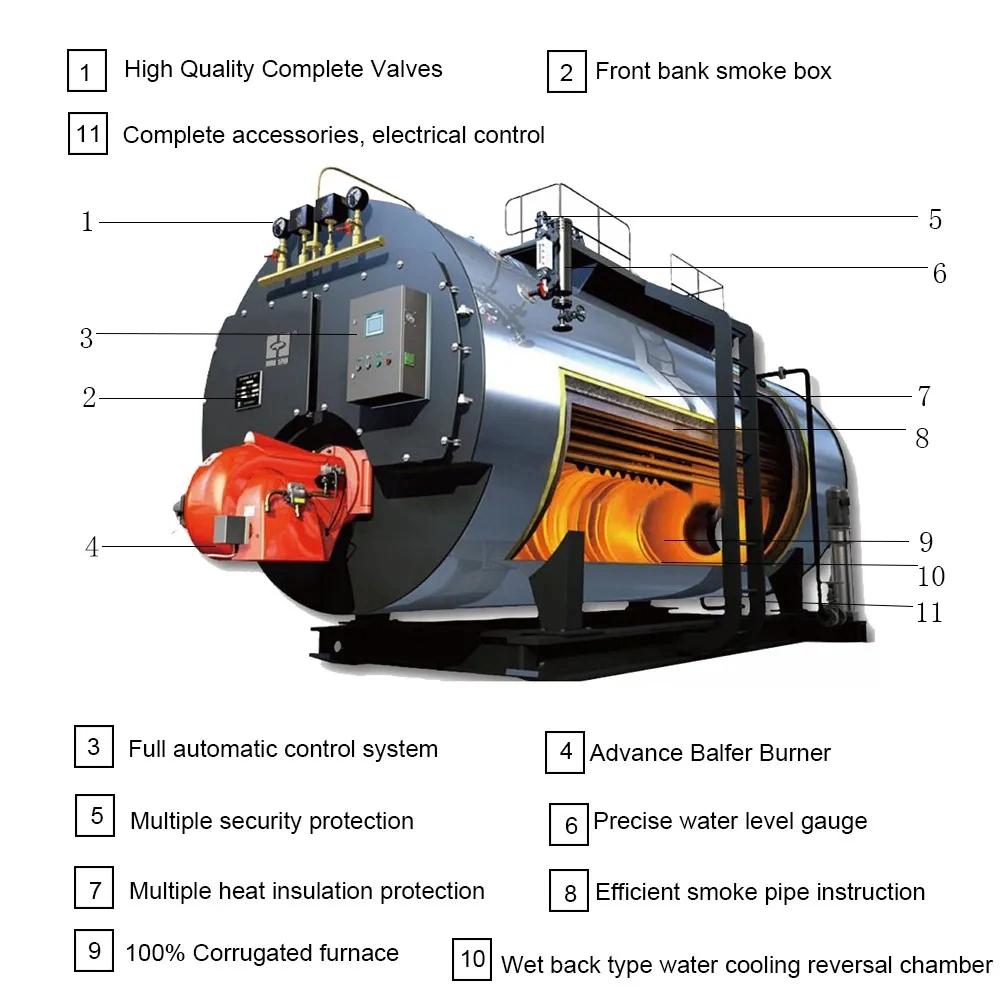

Características principales 1. La caldera de aceite tiene un diseño industrial inteligente y presta atención a los detal

Envíe su consultaDESCRIPCIÓN

Información básica

| N º de Modelo. | WNS2-1.25-YQ |

| Función | Calderas de vapor, caldera de aceite |

| Combustible | a gas |

| Instalación | Caldera empaquetada |

| Estructura | tubo de fuego |

| Medios de comunicación | vapor y agua |

| Circulación de agua | Circulación Forzada |

| Colocación del tambor | Caldera Horizontal |

| Presión | Presión |

| Nivel de fabricación | A |

| Estilo ardiente | Caldera de Combustión de Cámara |

| Uso | Industrial , Hogar , Vehículo , Central Eléctrica |

| Paquete de transporte | Desnudo con película plástica |

| Marca comercial | ALCANCE DE LA CALDERA |

| Origen | Porcelana |

| Código hs | 8402190000 |

| Capacidad de producción | 5000ton/año |

Descripción del Producto

N º de Modelo. | WNS0.5-1.0-Y/Q | WNS0.7-1.0-Y/Q | WNS1.0-1.0 | WNS1.5-1.0/1.25 | WNS2-1.25/1.6/2.5 | WNS3-1.25/1.6/2.5 -Y/Q | WNS4-1.25/1.6/2.5 -Y/Q | WNS5-1.25/1.6/2.5 -Y/Q |

Evaporación nominal | 0.5 | 0.7 | 1 | 1.5 | 2 | 3 | 4 | 6 |

Calificado | 1.0 | 1.0 | 1,0/1,25 | 1,0/1,25 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 | 1,25/1,6/2,5 |

Temperatura de vapor nominal. (ºC) | 184 | 184 | 184/194 | 184/194 | 194/205/220 | 194/205/220 | 194/205/220 | 194/205/220 |

Eficiencia | 93% | 93% | 93% | 93% | 93% | 93% | 93% | 93% |

Diesel | 32 | 42 | 61 | 90 | 120 | 184 | 243 | 300 |

Natural | 40 | 50 | 72 | 158 | 225 | 313 | 375 | 452 |

Salida de vapor | DN40 | DN40 | DN50 | DN50 | DN65 | DN80 | DN80 | DN100 |

Chimenea | Φ200 | Φ250 | Φ300 | Φ350 | Φ350 | Φ400 | Φ450 | Φ500 |

Peso (t) | 2.5 | 3.5 | 5.5 | 6.8 | 7.6 | 9.9 | 11.7 | 13.7 |

| Dimensiones totales (L*W*D(mm)) | 2950*1570*1820 | 3300*1620*1950 | 3650*1950*2200 | 4270*1800*2130 | 4650*2100*2450 | 4650*2200*2800 | 4800*2300*2800 | 6000*2600*2900 |

| N º de Modelo. | WNS6-1.25 /1.6/2.5-Y/Q | WNS8-1.25 /1.6-Y/Q | WNS10-1.25 /1.6-Y/Q | WNS12-1.25 /1.6-Y/Q | WNS15-1.25 /1.6-Y/Q | WNS20-1.25 /1.6-Y/Q |

| Evaporación nominal (t/h) | 6 | 8 | 10 | 12 | 15 | 20 |

| Presión nominal (Mpa) | 1,25/1,6/2,5 | 1,25/1,6 | 1,25/1,6 | 1,25/1,6 | 1,25/1,6 | 1,25/1,6 |

| Temperatura de vapor nominal. (ºC) | 194/205/220 | 194/205 | 194/205 | 194/205 | 194/205 | 194/205 |

| Eficiencia | 93% | 93% | 93% | 93% | 93% | 93% |

| Consumo de Gasóleo (Kg/h) | 354 | 472 | 580 | 707 | 849 | 1157 |

| Gas Natural (Nm³/h) | 452 | 627 | 770 | 926 | 1027 | 1330 |

| Salida de vapor (mm) | DN125 | DN125 | DN150 | DN200 | DN200 | DN200 |

| Chimenea (mm) | Φ600 | 700 | 750 | Φ800 | Φ900 | Φ900 |

| Peso (t) | 15.9 | 18 | 25.4 | 27.2 | 40 | 45.5 |

| Dimensiones totales (L*W*D(mm)) | 6300*2700*2900 | 6500*2950*3100 | 7400*3730*3540 | 8700*3730*3800 | 8870*4100*4500 | 10000*4500*5600 |

Productos relacionados

-

![Tubo de agua completamente automático Caldera de vapor de gas de aceite de combustible Generador de gas vertical Venta caliente de 3 fases]()

Tubo de agua completamente automático Caldera de vapor de gas de aceite de combustible Generador de gas vertical Venta caliente de 3 fases

-

![Caldera de planta de energía Hrsg Escape/caldera de vapor de reciclaje de calor residual de gases de combustión]()

Caldera de planta de energía Hrsg Escape/caldera de vapor de reciclaje de calor residual de gases de combustión

-

![Caldera portadora de calor orgánico de parrilla de cadena vertical en la industria maderera]()

Caldera portadora de calor orgánico de parrilla de cadena vertical en la industria maderera

-

![Modelo Dzl 0,7 1,4 2,8 4,2 5,6 7 10 14 MW Carbón Biomasa Madera Leña Calefacción central Caldera de agua caliente para invernadero Sala de deportes Escuela Edificio comunitario]()

Modelo Dzl 0,7 1,4 2,8 4,2 5,6 7 10 14 MW Carbón Biomasa Madera Leña Calefacción central Caldera de agua caliente para invernadero Sala de deportes Escuela Edificio comunitario